By signing in or creating an account, you agree with Associated Broadcasting Company's Terms & Conditions and Privacy Policy.

By signing in or creating an account, you agree with Associated Broadcasting Company's Terms & Conditions and Privacy Policy.

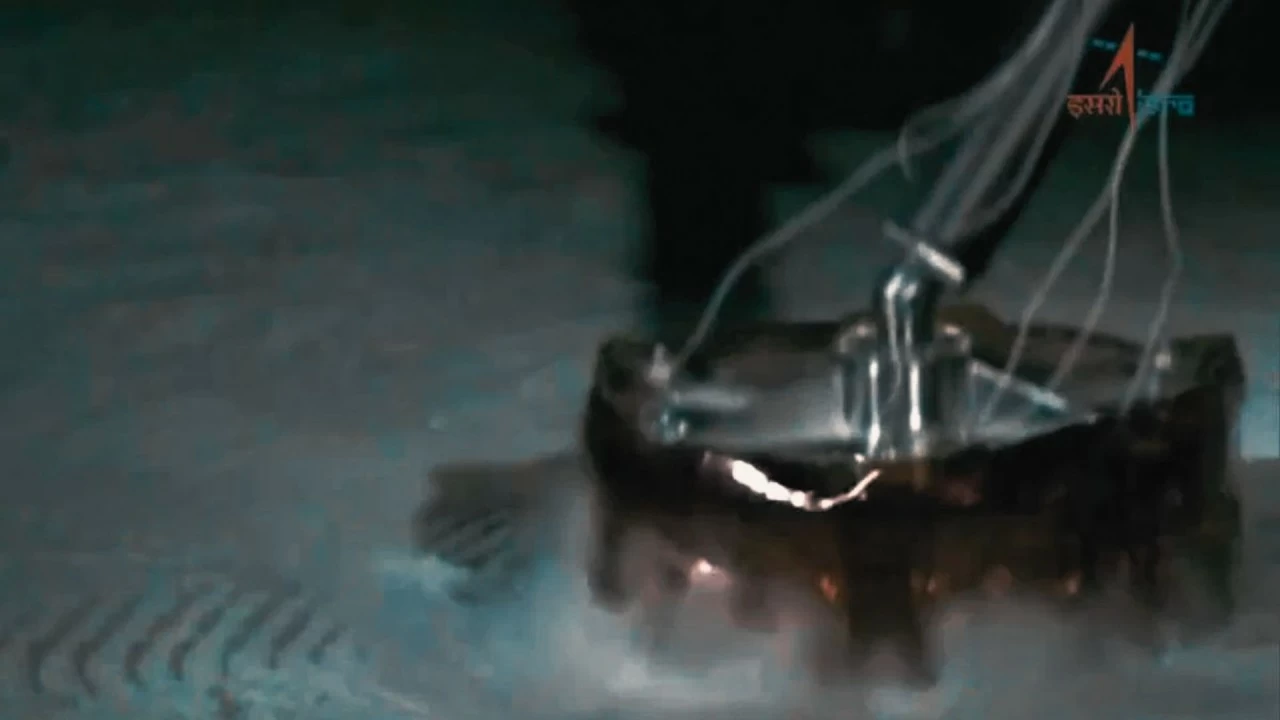

ISRO is making the legs used for the Vikram lander for technology transfer to Indian industries. The landing legs were initially developed for the Chandrayaan 2 mission, which crashed into the Moon on 07 September, 2019. An enhanced, fortified version was developed for the Chandrayaan 3 mission, which successfully landed on the Moon on 23 August, 2023. A number of New Space startups across the country have ambitious to operate o0n the lunar surface, and ISRO is now making the landing leg mechanism to any Indian industry partners who wish to use the legs for their own landers.

The UR Rao Satellite Centre in Bengaluru, that assembles most of the spacecraft launched by India is offering the Lander Leg Mechanism. The legs can accommodate landers up to 800 kg in mass. Four of these legs are designed to be attached to the lower deck of the Moon Landers. The main goal of the lander leg assemblies is to ensure a safe, soft landing on the lunar surface. The legs are designed for spacecraft approaching the lunar surface with a vertical velocity of less than two metres per second, and a horizontal velocity of less than 0.5 metres per second. The lander legs mechanism are designed for a maximum inclination of 12 degrees.

On the ground, ISRO has tested the lander legs beyond the specified capacities. The legs have telescopic damper assemblies that absorb some of the shock of the landing with a telescoping piston attached to the footpads. The footpads themselves have an advanced design, and use a honeycomb damper that crushes at the point of impact, absorbing additional shock. There is also a Knee Damper Assembly, that also absorbs some of the excess energy. The three cushioning assemblies together ensure that the lander can reach the lunar surface safely. Each of the subassemblies can be tested individually. ISRO also has a provision for sensing elements that indicate the crushing.